Working of the Wind Turbine components.

Wind is one of the fastest-growing energy sources in the world. When it comes to alternative clean power from renewable resources, wind power is expected to occupy the second-largest share of the market in the future after Solar. In this article, I have given an overview of the major parts of a Wind Turbine and their functions to generate electricity from wind.

Before we go into the working of the major Wind Turbine components to generate electricity let’s first take a look at the basic principle of how does a wind turbine work to harness energy from the wind.

Wind energy is a free, renewable resource. No matter how much is used today, there will still be the same supply of wind energy in the future. Unlike conventional power plants, wind plants emit no air pollutants or greenhouse gases. Even though the technology requires a higher initial investment than fossil-fuel-driven generators, the costs of wind generating systems are much more competitive with other generating technologies on a “life-cycle” cost basis because there is no fuel to purchase and operating expenses are minimal.

How does a wind turbine work – the basic principle

Wind Turbines, which operate on a simple principle, generate electricity by harnessing the power of the wind.

The energy in the wind turns two or three propeller-like blades around a rotor (as shown in the picture above). The rotor is connected to the main shaft of the turbine. When the wind blows on the angled blades of the rotor, it causes the rotor to spin thereby converting the kinetic energy of the wind into mechanical energy. Since the rotor shaft is connected to a generator through a gearbox, when the rotor spins, so does the generator. The rotating generator converts the mechanical energy at the shaft of the turbine into electrical energy by using an electromagnetic field.

Let’s now look into the roles played by the major parts of a Wind Turbine to make the turbine work.

Major parts of a Wind Turbine and their functions

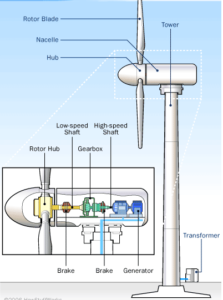

The working of the major Wind Turbine parts (shown in the diagram above) are detailed below to explain how wind turbines work to produce electricity:

The Nacelle

The Nacelle is the most important among all the parts of a Wind Turbine. It houses all of the Wind Turbine components including the generator, gearbox, and brake assembly.

The Nacelle sits on top of the tower and houses the low and high-speed shafts, the gearbox, the brake, and the generator. It also houses a Controller that receives data from an Anemometer, which measures wind speed, a Vane, which measures wind direction, a Pitch control system that controls the angle of the blades, and the Yaw drive, which controls the position of the turbine relative to the wind.

The wind vane on top of the Nacelle tells the controller where the wind is coming from. Wind direction determines the design of the turbines – whether upwind or downwind. The upwind turbines have the rotor in front of the nacelle facing the wind while downwind turbines have the rotor behind the nacelle and facing away from the wind.

The effect of the rotor orientation i.e. upwind or downwind has a dominating impact on the unsteady loads of the wind turbine system. When the wind changes direction, the Nacelle and the Rotor follow. The rotor should always be facing the wind in order to catch the wind properly. The controller of the wind turbine will always make sure that the rotor is turned into the wind. Nearly all wind turbines are of an upwind design.

Functions of Rotor and turbine blades

The Rotor is among the most important parts of a Wind Turbine which converts the kinetic energy of wind to rotary-mechanical energy.

The turbine blades and the hub together form the Rotor of a Wind Turbine. Most turbines have either two or three propeller-like blades. The hub is one of the main Wind Turbine parts that connect the blades to the main shaft and ultimately to the rest of the drive train that transfers rotational mechanical power from the rotor hub to the electric power generator.

The rotor is connected to the main shaft of the turbine. The energy in the wind turns the turbine blades around the rotor, which spins the power generator and the generator converts the mechanical energy at the shaft of the turbine into electrical energy by using an electromagnetic field. Thus the role of the turbine rotor practically explains, how a Wind Turbine generates electricity.

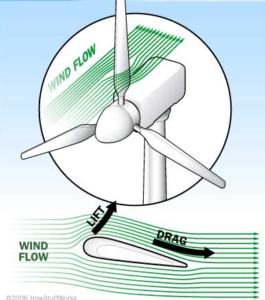

The turbine blades work by generating lift and drag due to their difference in shape when the wind blows over them, like an airplane.

The two primary aerodynamic forces that work in wind-turbine rotors are ‘lift’, which acts perpendicular to the direction of wind flow, and ‘drag’, which acts parallel to the direction of flow. The blades of a wind turbine are shaped with one side (rear) much more curved than the other side (front). This varied shape causes a pressure differential when the air moves across the blades. The low-pressure air pocket on the downwind side of the blade pulls the blade towards it, causing the rotor to turn, which is called lift. The wind’s force against the front side of the blade is called drag.

The force of the lift is actually much stronger than the wind’s dragging force. The net result is a lifting force perpendicular to the direction of flow of the air over the turbine blades which creates torque in the Wind Turbine rotor and causes it to spin like a propeller.

Functions of the main shaft

The low-speed shaft, which is the main shaft of the turbine, has important functions. It supports the rotor (hub and the blades) and drives the high-speed shaft connected with it through the Gear Box which is one of the major parts of a Wind Turbine.

The low-speed shaft transmits the rotary motion of the rotor and the torque momentum to the high-speed shaft through the Gear Box to drive the generator.

The role played by the Gear Box

The power from the rotation of the Wind Turbine rotor is transferred to the generator through the power train, i.e. through the low-speed shaft (the main shaft), the gearbox, and the high-speed shaft. The rotor of the Wind Turbine rotates at a relatively slow speed. With a gearbox, this slowly rotating, high torque power from the rotor is converted to high-speed, low torque power, which is needed for the generator connected to the high-speed shaft. The Gear Box increases the rotational speed of the generator from about 15 to 20 rotations per minute (rpm) for a large, one-megawatt turbine to about 1,800 revolutions per minute which most generators need to generate electricity.

The role played by the Controller

To optimize the functionality of a Wind Turbine, a controller is used, which is one of the most important Wind Turbine parts.

The controller increases power production and limits the loads on the structural parts. The control system consists of a number of computers that constantly monitor the condition of the wind turbine and collect statistics of operation from the sensors. The controller continually optimizes the energy production based upon continuous measurement of mainly wind direction and wind speed. It starts up the machine at wind speeds of about 8 to 16 miles per hour (mph) and shuts off the machine at about 55 mph.

Turbines do not operate at wind speeds above 55 mph because the high winds may damage the turbines.

The braking system

The braking system is one of the important parts of a Wind Turbine. This system stops the rotor automatically when its rotational speed exceeds its cut-out point to prevent any mechanical or electrical damage. The primary braking system for most modern Wind Turbines is the aerodynamic braking system which stops the turbine in a matter of a couple of rotations. In addition, the aerodynamic braking system offers a very gentle way of breaking the turbine without any major stress, tear, and wear on the tower and the machinery.

The function of the Generator

The Wind Turbine generator converts the rotational mechanical power generated by the rotor blades into electrical energy. The wind pushes directly against the blades of the turbine, which converts the linear motion of the wind into the rotary motion necessary to spin the generator rotor to produce electricity by using an electromagnetic field.

All Wind Turbines have certain characteristics related to wind speed. The generator (or alternator) will not produce output power until its rotational speed is above its cut-in wind speed where the force of the wind on the rotor blades is enough to overcome friction and the rotor blades accelerate enough for the generator to start generating electricity. Above this cut-in speed, the power output from the generator would rise as a cube of wind speed (i.e. if wind speed doubles, the power output increases eight times) until it reaches its maximum rated power output. If the wind speed continues to increase, the Wind Turbine generator would stop automatically at its cut-out point to prevent any mechanical or electrical damage.

The function of the Pitch system

The Pitch system in a Wind Turbine is a closed-loop drive system that controls the angle of the turbine blades by rotating them so that the blades use the right amount of the available wind energy to get the most power output, at the same time ensuring that the turbine does not exceed its maximum rotational speed. This maintains the turbine’s safety in the event of high winds, loss of electrical load, or other harmful events.

The role played by the Wind Turbine Tower

Wind Turbines are mounted on a tower to capture energy from the wind. The main body of the turbine sits on top of the tower and behind the blades. The tower of a Wind Turbine supports the Nacelle and the Rotor (the hub with three attached blades). The taller towers enable Wind Turbines to capture more energy and generate more electricity because the wind speed increases farther away from the ground and the wind blows more steadily at a higher atmosphere.

You may also like to read this post: Wind energy advantages and disadvantages

Frequently asked questions

Now that the major parts of a Wind Turbine and their functions have been explained to show how does a Wind Turbine work, let me also address some of the related questions often asked by people.

How does a Wind Turbine work when it is not windy?

If the atmosphere is not windy or if there is too little wind and the blades move slowly, the Wind Turbine may not produce any electricity. There is a ‘cut-in speed’ at which the turbine starts to produce electricity. Power output continues to grow as the wind speed increases.

Why do Wind Turbines have 3 blades?

Fewer blades in a turbine reduce drag. But turbines with two blades will vibrate when they turn to face the wind. The angular momentum stays constant in a turbine with three blades. This is because when one blade is up, the other two points at an angle, and the turbine can rotate into the wind smoothly.

What are the parts of a Windmill?

The major parts of a Windmill are – the Tower, Rotor, Nacelle, Generator, Blades, and foundation.

How much energy comes from wind in the United States?

Wind power supplies about 6% of total U.S. electricity generation with an installed capacity of over 80 GW, which is enough to power 24 million homes.

You may also like to read the related post: How does Wind work as a source of energy

Conclusion

It is hoped that after going through the major parts of a Wind Turbine and their functions explained above there should not be any difficulty in understanding how does a Wind Turbine work to harness energy from the wind to generate electricity.

The working of the main Wind Turbine parts can be summarized as follows:

1. One of the major Wind Turbine components is its Rotor. When the wind blows on the angled blades of the turbine which are attached to the rotor, it causes the rotor to spin thereby converting the kinetic energy of the wind into mechanical energy;

2. The rotor is connected to the main shaft of the turbine. The rotor shaft is connected to a generator through a gearbox. The gearbox converts the low-speed rotation of the drive shaft into high-speed rotation fast enough to drive the generator and convert the mechanical energy at the shaft of the turbine into electrical energy by using an electromagnetic field;

3. The electric current produced by the generator flows through a cable running down the inside of the turbine tower;

4. A step-up transformer converts the electricity to a higher voltage so that it can be transmitted to the power grid;