How does the control system in robotics work?

Every beginner needs to understand what is robotic control and how do Robots work. In this article, I have explained the control system in robotics which helps to control the movements of robots that carry out a wide range of activities with speed and precision to aid humans.

Today there is countless application of robotics in areas such as material handling, transporting heavy things, automated manufacturing processes, self-driving cars, health care applications, and many more. I have explained here, the concept of robotics control as an introduction to how the robot control system efficiently programs a robot’s activities like physical movements, rotations, path planning, and more.

The robot control for controlling movements of robots can be done in various ways which include manual control, wireless control, and fully automatic control using Artificial Intelligence to have the robot move on its own. Automation plays an integral part and vital role in Robotics operations. With technological advancements, the robotic control system continues to develop and advance.

Before I go to explain the robot control system let’s first see how do robots work.

You may also like to read: Important Facts about Artificial Intelligence

How do robots work?

A robot is an autonomous machine that has the following 3 main parts. All of these parts work together and explain how do robots work.

1. Controller – The robot controller controls the movements and functions of the robot. The robot controller is a feedback control system, run by a computer program that gives commands for the moving parts of the robot to follow. The controller stores information about the robot and its work environment and contains programs that operate the robot;

2. Actuator – The Actuators (such as motors, pistons, grippers, wheels, and gears) are used to produce mechanical movements of the robot elements to make the robot move, grab, turn, or lift. The source of energy that the actuators require to create motion is usually electricity, hydraulic fluid, or pneumatic pressure;

3. Sensors – The sensors give the robots an awareness of their environment or surroundings and other important information. The sensing elements feed measurements and details like sizes, shapes, space between objects, direction, etc. to the robot controller which processes them and then sends back the control signal making necessary changes, to activate the actuators to enable appropriate robot control.

Robotic Control system explained

The control system in robotics manages commands and directs, or regulates the movement and function of various parts of the robot to achieve the desired result. The essential requirement of any robotic control installation is automatic control of robot motion. Every robot has a controller which is a type of feedback control system. It continuously reads from sensors and updates the commands for the actuators so as to achieve the desired robot behavior. The robot controller coordinates and controls all aspects of the operation of the robot. Now let’s see how the robotic control system works.

In order to achieve high levels of performance, the robotics control uses a closed-loop control system making use of sensor feedback as explained below.

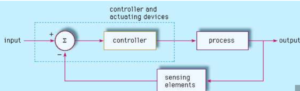

A feedback control system consists of five basic components which are,

1. Input;

2. Process being controlled;

3. Output;

4. Sensing elements;

5. Controller and actuating devices;

What is a closed-loop robotic control system?

A control system that makes use of feedback is called a closed-loop control system. In closed-loop feedback control, the controller compares a measured output value of a process with the desired set value which is the reference or set point.

The output value is fed back through the ‘sensing elements’ for comparison with the reference value. The difference between the actual output value and the desired set value of the process is the ‘error’ signal. This error signal is fed into the controller which generates a control action making necessary changes in the input signal to the ‘process’ under control so that the output value of the process gets to the desired set value.

The concept of a closed-loop robotic control system can be diagrammatically represented as below:

The robot controller which controls the robot’s movements can be considered the Robot’s brain. The basic theory related to the robotic control system is that an input signal is generated in response to a program command for achieving a specific goal, which produces an output signal from the controller that activates an actuator to produce mechanical movements of the robot elements.

The smarter the programming of the control algorithm, the more reliable and efficient the control system. The robot’s motion and forces are measured by ‘sensors’ that send the measurements back to the robot controller. Using the reference set point and the sensor feedback the robot controller makes changes that are required in the control signal to reduce the system error and bring the output of the system back to the desired set value.

Frequently asked questions

Now that I have explained the closed-loop control system in robotics and how do robots work let me also reply to some of the questions related to robotic control often asked by people.

What are the major types of robotics control?

There are two basic control systems of robots:

1. Point-to-point control system of the robot: With this control system the robot can know the point where to pick up a part and the point where to release that part. This system works while loading and unloading applications;

2. Continuous path control system of a robot: This control system is used for jobs when the robot is required to follow a specific path, such as in welding or painting;

How can we control robots?

Robots can be controlled in various ways which include manual control, wireless control, and fully automatic control using Artificial Intelligence.

What is the difference between Robotics and Robots

Robotics is a branch of technology that deals with physical robots whereas Robots are programmable machines that carry out actions automatically or semi-automatically.

Can robotics replace human employment?

Robotics can replace humans in many types of jobs. Factory floors are increasingly deploying robots driven by machine learning algorithms so that they can adjust to people working alongside them.

You may also like to read this related article: Benefits of RPA – Robotic Process Automation Use cases

Conclusion

In short, a robotic control system manages commands, directs, or regulates the movement and functions of various parts of the robot, as well as executes a specific set of forces and motions. In a closed-loop robot control system the actuating error signal, which is the difference between the actual output value and the desired set value of the process, is fed into the robot controller in order to reduce the error and stabilize the output of the system so as to achieve the desired robot behavior.

This post tries to give a broad and, hopefully, easy-to-understand basics of how do robots work and the fundamentals of the control system in robotics.